Start with a rod of steel, and cut off little pieces slightly larger than the volume of the ball. Then progressively forge them slightly round with little dies, then roll them through 2 parallel plates , one of which has a spiral groove cut on its work surface. Think of two discs pressed together spinning opposite, like the spiral videos that are supposed to make you dizzy, for one disc, the other just a flat plate perhaps with some abrasive textured surface. These plates start out at a slightly greater separation, but as they spirals towards center they close in to the diameter of the ball. The balls are loaded on the outside, the top plate is spinning, the balls roll towards the center and fall out at the center really round. This machine made balls for Ford power seats at one factory I went to. At some point heat treat for hardness. Then put balls into a vibratory polishing machine. This machine uses stones, water, and grit, while vibrating heavily, probably for many hours. Eventually the balls get really round. Remove the balls. Measure them at high speed and sort them out by size. One simple test is dropping the balls onto a tilted metal plate where they bounce off into a small hole in the wall. Ones that miss are rejects. One can pick 100 balls all within one millionth of an inch, sell that as and super prescise set. Pick out thousands within .00001 up to .0002 or more and sell those for junky consumer junk, made to be cheap junk. With balls, one gets the process to repeat, then sort out the balls to select the ones that came out correct to the desired size within increasingly larger tolerances, less accurate will sell for less money, and dispose or process to smaller size the rejects. In short, one makes thousands of balls striving for a given size, then selecting the balls that came out correct for sale.

A bearing is a mechanical component which is used to transfer loads with very minimal friction at high speeds.

Bearings are of different types, among which ball bearing is the widely used one right from cycles to bigger machines.

Construction of a ball bearing:

Ball bearing consists of four main parts as follows:

· Inner Race – This is the part that is mounted on the rotating shaft and tends to rotate the shaft.

· Outer Race – This is the part that is mounted to the housing and is stationary. This also serves as a means for transferring the loads from the bearing to the housing.

· Rolling Element “Balls" – These are the elements that carry the load distributing it throughout the raceways. They tend to rotate about the inner race, but not at the speed the inner race rotates. It is something like the relation between the earth and the moon.

· Cage – This is an important element in the bearing. This acts as a barrier between the balls preventing them from bumping into each other.

Working:

The balls are placed in the inner race and the outer race is placed on top of the balls. The cage is used to prevent slippage and bumping of the balls with each other.

Once the load is to be transferred, the balls runs along the outer race and thereby transferring the load with very minimal friction.

Load Carrying Capability:

Ball bearing has a good capability to run at high speeds but average in carrying loads. They are able to carry only medium loads and hence find use in almost all the household items such as ceiling fans, Mixes, Grinders, etc..

Ball bearings are usually used for freewheel mechanisms. In other words, it is used to lower the friction and increase movement due to its highly spherical and smooth surfaces.

Metal balls are used mainly in freewheel mechanisms, roller applications and other demanding industrial applications. The surface is highly finished and hardened for a high load capacity.

The outer portion of the balls are traditionally made of thin steel, but some bearings now use molded plastic cages, because they cost less to make and cause less friction.

Ball bearings have got a very large variety of use in different industries like:

Ball bearings have got a very large variety of use in different industries like:

1. The Automotive Industry

2. Paper Making Industry

3. Home Appliances

4. Toy Industry

5. Aerospace

and many more….

SKF Ball bearings reduce friction by using smooth balls lubricated with oil or grease that freely roll between a smooth inner and outer surface. The main concept of the ball bearing is that objects that roll past each other produce less friction than if the objects were sliding against each other.

Ball bearings are typically mounted in rotating assemblies in which one race is stationary, such as the outer race when pressed into a housing, while the other race rotates with the shaft. The separation of the races by the balls reduces the friction that would've been present between the shaft and housing. The balls allow the inner race of the bearing to rotate independently of the outer race while also carrying the load transmitted through the races.

They are generally used in instruments and machines to reduce friction and power loss.

These bearing types are designed to bear both radial and thrust loads and are found in different daily objects such as bicycles, photocopiers, DVD players, blenders, skateboards, and more. Because of their affordability and versatility, used in several industrial applications. There is a wide variety of bearings with different shapes, seals, and locking methods. These bearing types work by shifting the load from the external race to the ball and then to the inner race. Apart from daily objects, ball bearings are also used in many technical applications, including weather satellites, the Mars Rover, and the Hubble telescope. They continue to be an affordable choice for a different portfolio of products and industries.

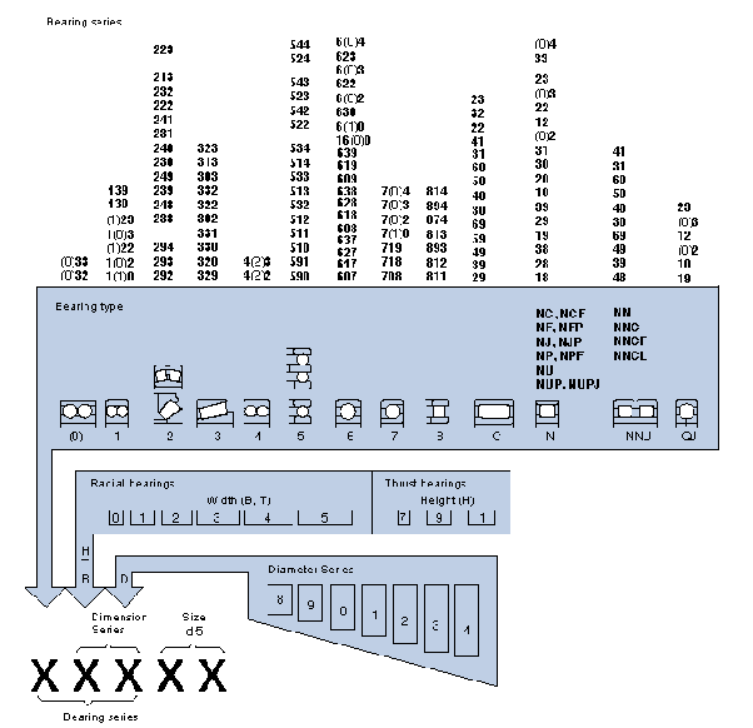

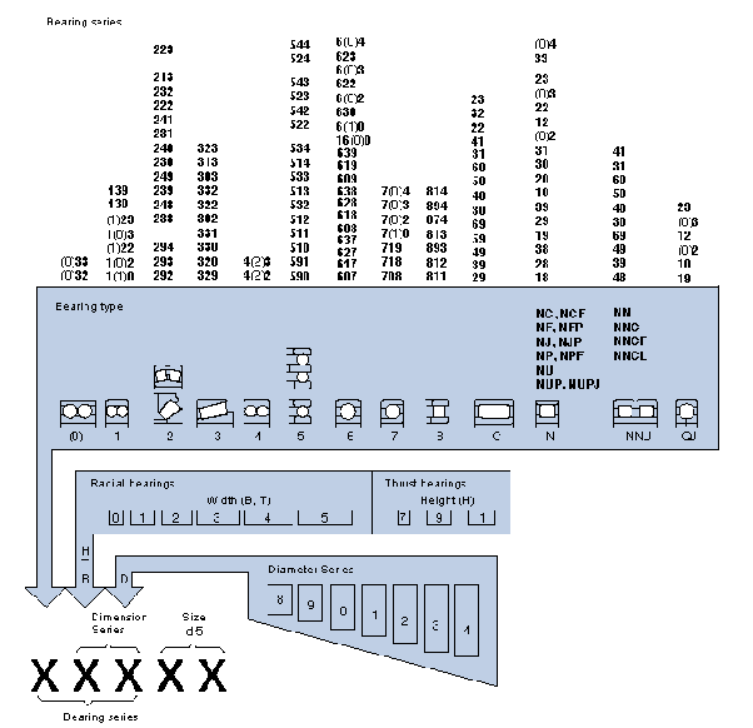

Most bearing manufacturers follow the ISO-15 designation system. With it, you can calculate the inner and outer dimension and width from the last 4 digits of the designation number, just like that “6210” mentioned in the question, which actually corresponds to 60210,as the zero is ommited

In short:

Calculate the inner diameter d, in mm, by multiplying the last 2 digits by 5: 60210 → 10 → d=50mm (there are exceptions for 01, 02, 03).

Find the bearing diameter series multiplier, f0, from the diameter series number, which is the 3rd digit of the code: 60210 → 2 → fD=1.48.

The outer diameter, D, in mm is given by D=d+fD*d^0.9 for radial bearings, thus 60210 → D=100.042 → D=100mm. Which is wrong somehow because in all catalogs D=90mm for this particular bearing.

News

News